Design / Development

Our highly experienced designers create designs that incorporate manufacturing engineering requirements to ensure practical and efficient production.

We provide innovative design solutions that meet our customers’ quality requirements.

Leveraging highly efficient lean production process, we develop cost-effective, easy-to-manufacture products and in-house equipment.

Our research and development efforts focus on innovative materials and manufacturing methods, anticipating the needs of the next generation

We are actively researching materials that respond to social demands, including environmentally friendly alternatives.

By embracing free-thinking rather than adhering to conventional frameworks, we continuously evolve traditional manufacturing methods and pursue the creation of new value.

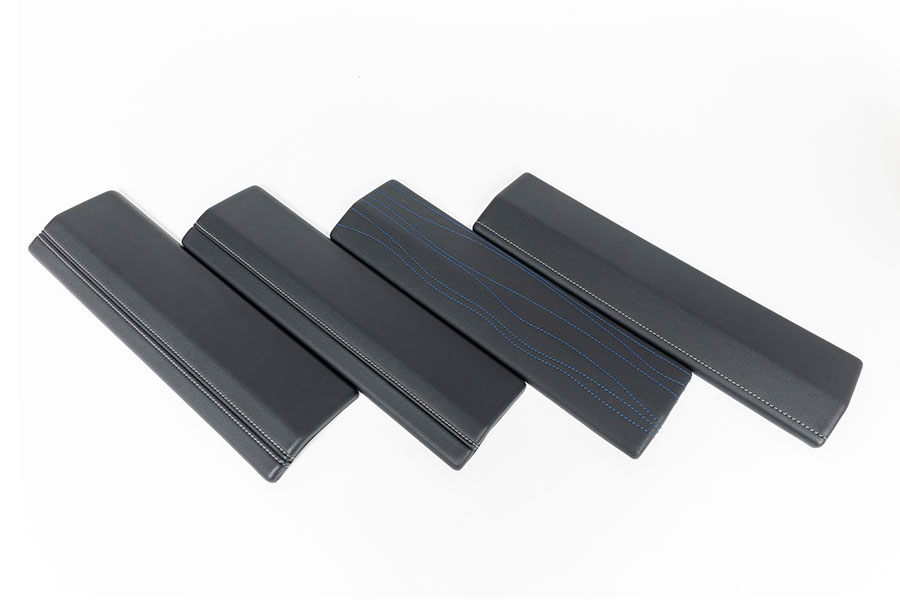

“mamo” (Multiple All-in-One Molding Operation) is our patented process that integrates vacuum forming and sewing technologies. Its enhanced version, “e-mamo,” offers superior performance and expanded capabilities.

This proprietary technology enables the molding of outer skin materials into a single piece with integrated stitching -an achievement previously considered difficult with conventional vacuum forming methods.

The flexible combination of various skin types and stitching patterns also makes it highly suitable for grade differentiation and management.

Production preparation

Our process design methodology balances worker comfort, labor-saving and automation strategies, along with the development of jigs and tools, and the coordination of mold design.

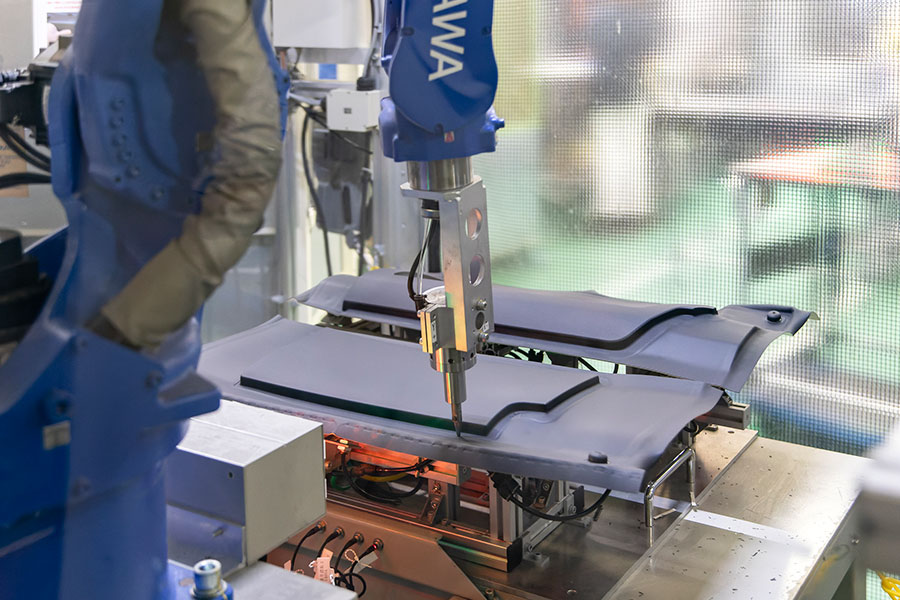

Automed assembly process and development of unique processes

We actively promote labor-saving initiatives through the implementation of various automated machines, while also developing proprietary processes tailored to our production needs.

Our focus is on the development of proprietary tools specifically designed to advance automation efficiency.

We actively pursue the research and development of proprietary tools that go beyond what is offered in commercially available solutions.

Reducing production preparation time to improve overall efficiency.

In pursuit of efficient in-house jig evaluation and shorter production lead times, we have introduced equipment for internal jig fabrication.

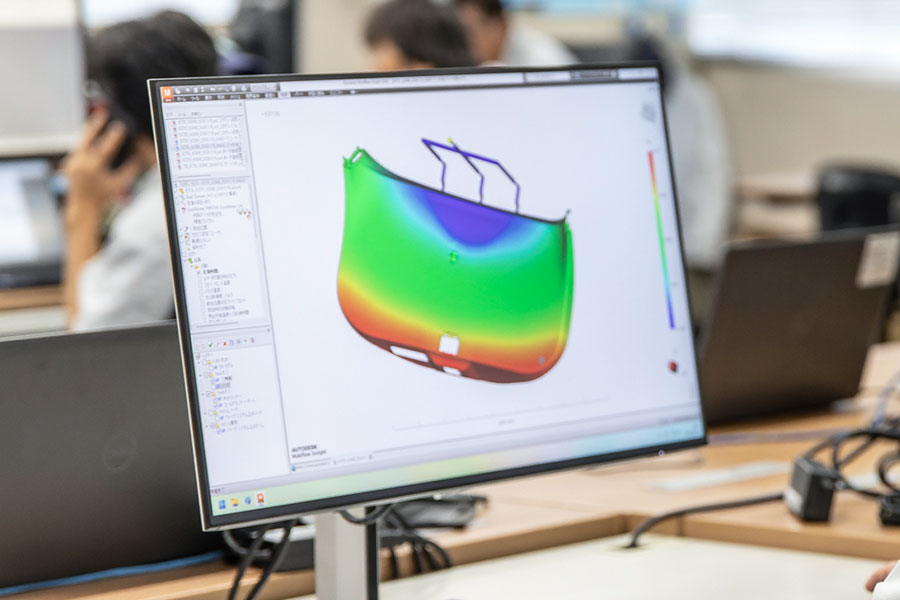

Mold design and preparation

Before initiating mold design, we perform flow and warpage simulations to ensure the most suitable mold structure is developed for each product.

Visualization of the production line

By leveraging IoT to digitize and visualize real-time conditions on the production line, we aim to detect issues at an early stage and drive continuous improvement. These efforts contribute to enhanced production efficiency and strengthened quality management.

Quality evaluation

Quality evaluation for interior / exterior parts

We collaborate closely with our customers to establish highest quality standards and support stable production.

Inspection jig specifications are developed based on these standards to ensure accurate and consistent evaluations.

We also utilize dedicated inspection cells and inspection tools to verify product quality and conduct defect analysis.

Performance evaluation

We perform comprehensive specification testing across a broad range of areas -from basic material properties, environmental resistance, impact testing and air bag demployemnt and simulation – based on customer specifications and standards.

Vibration test

Environment duability test

Physical property test

Light resistance test